Non Woven Clothes

Aniket International also resale Non-woven fabric

range manufactured by M/s.Surya Textech, Himachal Pradesh and M/s.Alpha Foam

Ltd., Maharashtra.

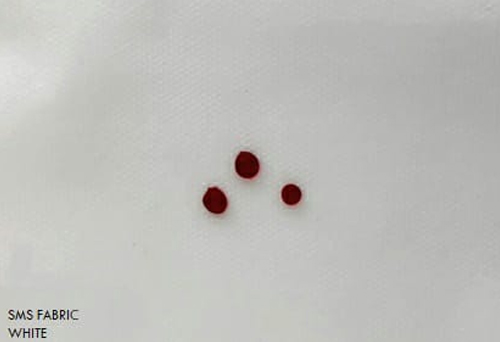

SMS Non Woven Fabric

It is produced on triple beam spun-melt line for

medical & hygiene application. This fabric is hydrophobic in nature that

offers good hydrohead barrier for Diapers, Surgical Gown, Drapes,

Sterilization Wrap and surgical kit. For hygiene segment, we offer SMS in

two GSM 13 and 15 in natural white shade with super-soft quality, in desired

width from 100 mm to 1600 mm.

For surgical segment we offer 25, 35, 43 and 50 GSM in three blue shades and 25 and 40 GSM in white shade. The width can be maximum 1750mm for surgical segment SMS.

For surgical segment we offer 25, 35, 43 and 50 GSM in three blue shades and 25 and 40 GSM in white shade. The width can be maximum 1750mm for surgical segment SMS.

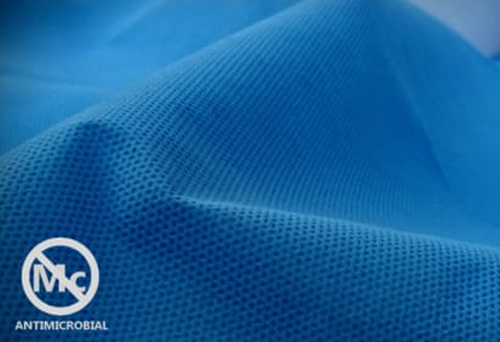

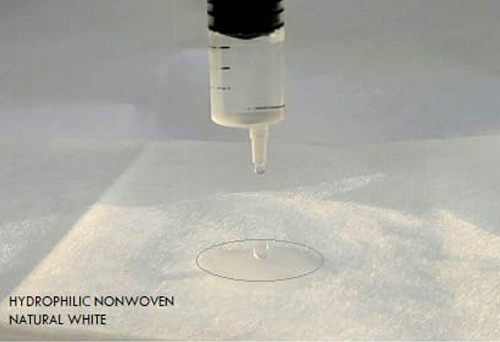

SS Non Woven Fabric

SS Fabric is made on double beam line, It offers

super soft quality for hygiene, medical and surgical segments. This fabric

offers versatility and customization through value added treatment to meet

demand of various challenging applications. Some of the value added/treated

qualities with their applications are listed below :

Our SS non woven fabrics are made from highest grade PP and world class additives for achieving softness and best of physical parameters. We offer our SS fabric in GSM range of 8-160, and width from 100 mm - 1600 mm in desired slit sizes. More than 95% rolls are supplied joint free and in uniform length.

- Hydrophilic - hygiene segment

- UV stabilised - Agri & Outdoor usage segments

- Antistatic - Medical & Surgical Segments

- Antimicrobial - Medical Segment

- Fire Retardants - Fire safety segment

Our SS non woven fabrics are made from highest grade PP and world class additives for achieving softness and best of physical parameters. We offer our SS fabric in GSM range of 8-160, and width from 100 mm - 1600 mm in desired slit sizes. More than 95% rolls are supplied joint free and in uniform length.

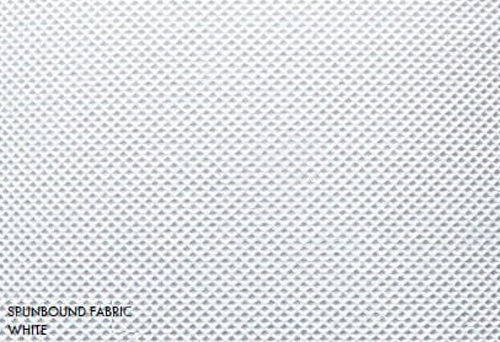

Spunbond Non Woven Fabrics

PP spunbond fabric are well known in the packaging

and shopping bag industry. Its micro dot patterns, even fibre distribution,

consistent whiteness & flat surface provide best resources to offset

printers for creating sharp images on non-woven fabric and bags.

Our Non Woven fabric offers better tensile strength both on MD/CD, offers precise firmness for desired body shape of bag. It also delivers longer shelf life with sustained print quality. It has been possible with a decade of experience and use of virgin grade raw material - polypropylene. Our GSM range is from 16 to 160 and width up to 3200 mm.

Our Non Woven fabric offers better tensile strength both on MD/CD, offers precise firmness for desired body shape of bag. It also delivers longer shelf life with sustained print quality. It has been possible with a decade of experience and use of virgin grade raw material - polypropylene. Our GSM range is from 16 to 160 and width up to 3200 mm.

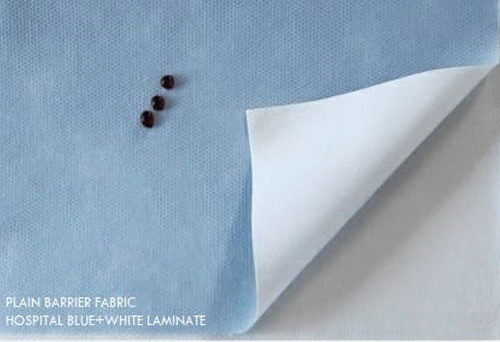

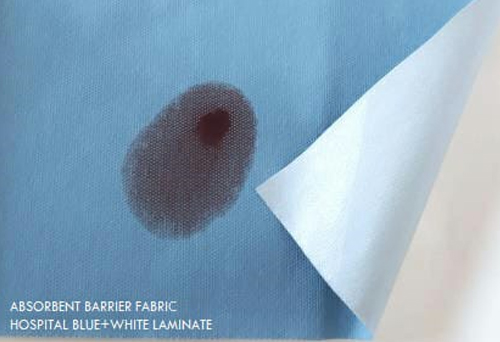

Laminated Non Woven Fabrics

We offers laminated non woven fabric for packaging,

medical, surgical & hygiene segments. We do lamination through extrusion

method in consistent soft quality, it offers flexibility and affordability

to our customers. Some of the key varieties of our laminates are listed

below with their respective applications.

Our BOPP laminates and PE/PP laminates are very popular in packaging segment, their uniform thickness, softness, better printability offers better processing capabilities and product differentiation to packaging and premium shopping bag manufacturer.

- Absorbent Barrier Fabric (AB Range) - Surgical Segment

- Plain Barrier Fabric (PB Range) - Surgical Segments

- Absorbent Trilaminates (AT Range) - Surgical, Consumer product segments

- BOPP Laminates - Premium shopping Bag segment

- Spunbond PP/PE laminates - Packaging Segment

Our BOPP laminates and PE/PP laminates are very popular in packaging segment, their uniform thickness, softness, better printability offers better processing capabilities and product differentiation to packaging and premium shopping bag manufacturer.